Grader

- Model

717T,719T,722T

- Rated power

128KW,140KW,162KW

- Weight(T)

14.5,15.6,16.1

- Discharge standard

National II

Email:[email protected]

Motor grader is the main machinery used for shaping and leveling operations in earthworks, and is widely used in large-area ground leveling operations such as highways and airports. The motor grader has a wide range of auxiliary working capabilities due to its moldboard ability to complete 6 degrees of movement in space. They can be done individually or in combination. In the construction of the roadbed, the motor grader can provide sufficient strength and stability for the roadbed. Its main methods in subgrade construction are grading, slope brushing, and embankment. Motor grader is a kind of high-speed, efficient, high-precision and multi-purpose earthmoving machine. It can complete the ground leveling and trenching, scraping, bulldozing, snow removal, loosening, compaction, cloth, mixing, auxiliary loading and land reclamation in large areas such as important highway content fields and farmland. It is an important equipment in the construction of national defense engineering, mine construction, road construction, water conservancy construction and farmland improvement. Highway subgrade is the foundation of the pavement and an important part of highway engineering. The roadbed bears the traffic load from the pavement and is a supporting structure of the pavement, which must have sufficient strength, stability and durability. Depending on the terrain, highway subgrade generally adopts two forms: embankment and cutting.

| Model | Rated power | Weight(T) | Size(mm) | Grader blade length(mm) |

| 717T | 128KW | 14.5 | 8630*2600*3370 | 3658 |

| 719T | 140KW | 15.6 | 8935*2600*3370 | 3966 |

| 722T | 162KW | 16.1 | 8935*2600*3370 | 4320 |

Pretreatment production line: large-scale dissipation treatment equipment, steel plate than the thickness of the treated sheet metal can be between 6~80mm, width 1000~3000mm, to meet the pretreatment of all incoming materials

HSDY CNC forging and shaping equipment: the maximum pressure is 500 tons, the workpiece can be up to 6 meters, and the CNC operation is accurate, high efficiency and good forming

Welding robot machining center: imported by Austrian IGM company, welding penetration is large, high strength, can operate continuously for 24 hours, and the quality reaches Komatsu KES standard

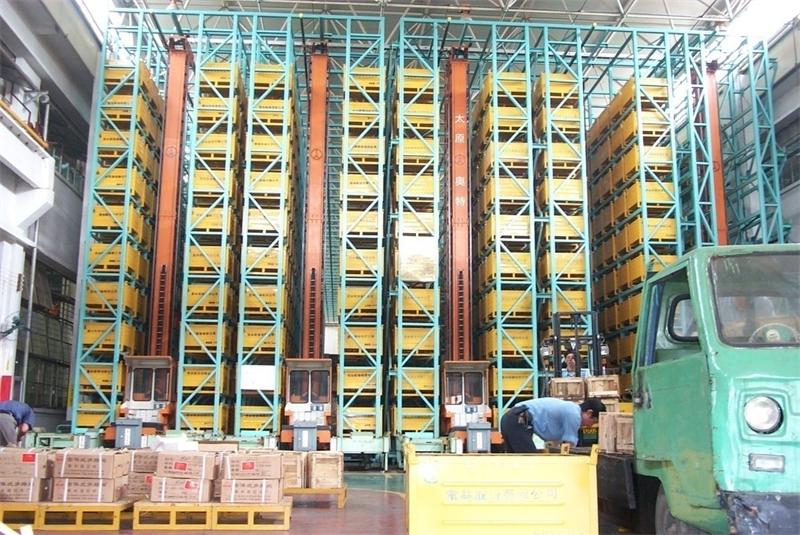

Parts warehouse: spacious parts warehouse, equipped with assembly line transmission system, three-dimensional shelves.

Neat machining workshop: equipped with Italian M7 vertical horizontal type, Sweden HMC800 horizontal type, American T30 horizontal type and other CNC machining equipment to ensure that the machining accuracy meets the design requirements

Assembly line assembly workshop:

Please feel free to contact us, fill out the form below and one of our representatives will contact you as soon as possible.